Transforming personalized medicine with AI-driven CAR-T manufacturing

Automated CAR-T cell production platform is ready for production

Advertisement

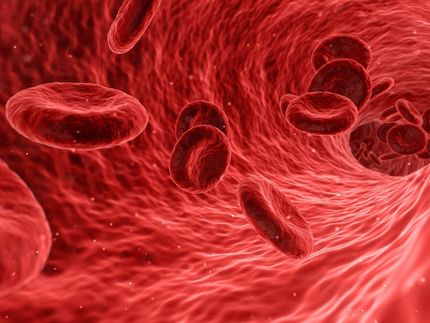

The EU-funded project AIDPATH (AI powered, Decentralized Production for Advanced Therapies in the Hospital), a collaboration between twelve partners from seven countries, is aiming to increase patient’s access to CAR-T cell therapy, a promising treatment for blood cancers such as leukemia and lymphoma. After developing a platform for automated CAR T production, the first manufacturing part of the platform has been moved to its final location at the University Hospital Würzburg, where first tests have been already conducted. This unique platform will now undergo further rigorous testing to ensure that it meets the highest standards of precision, safety, and efficiency by utilizing AI technology to manufacture genetically engineered immune cells.

Promising therapy

The CAR-T manufacturing process involves genetically modifying a patient’s own T-cells to express a synthetic chimeric antigen receptor (CAR), enabling them to effectively target and destroy cancer cells. Though this therapy has already shown great promise, there are significant challenges that hinder its wider application, including high manufacturing costs as well as complex procedures and logistics. “This automated system will allow to produce CAR-T cells and other Advanced Therapy Medicinal Products (ATMPs) directly at the point of care, offering a decentralized and more efficient manufacturing approach to CAR-T cell therapy”, Prof. Michael Hudecek, Chair of Cellular Immunotherapy at University Hospital Würzburg and Head of Department of Cellular Immunotherapy at Fraunhofer IZI, points out.

A smarter approach to manufacturing

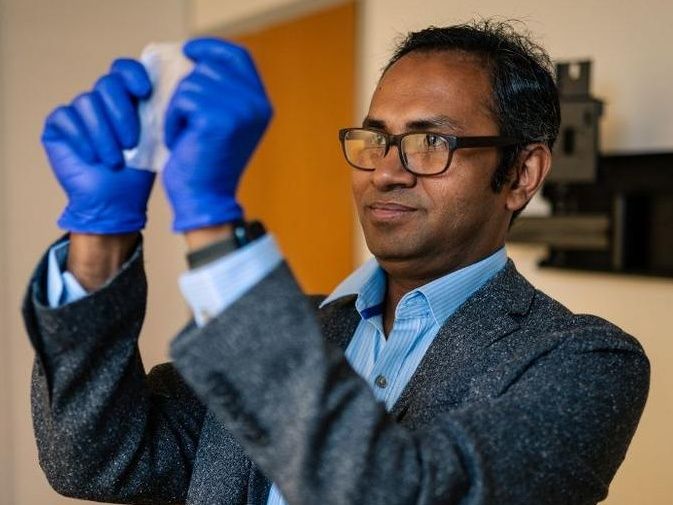

The new platform at the University Hospital Würzburg utilizes an innovative, end-to-end automated manufacturing system that integrates AI-powered digital twins, advanced production scheduling tools, and real-time process monitoring.

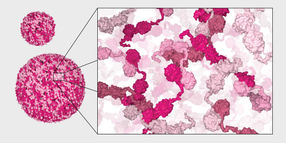

With the help of AI, the platform will be able to integrate clinical and physiological data of the patient and the cells to define a patient-specific manufacturing process tailored to generate an optimal and truly personalized CAR-T cell product. In addition, AI will predict production capacities and optimize the use of hospital resources. The goal is to make CAR-T cell therapy more accessible to patients while ensuring the highest levels of quality and consistency in production.

Continual improvement using real-world data

The platform collects and generates patient data within Ortec Logiqcare’ s centralized, cloud-based data infrastructure, LogiqSuite, which is customized to support AIDPATH-specific processes. By integrating patient medical data, therapy production data, and therapy monitoring data, the platform enables the implementation of a continual improvement cycle. The algorithms are continually optimized, in a quality-controlled process, using the increasing volume of data collected from connected decentralized manufacturing sites.

A partnership that benefits patients, hospitals, and the biotech industry

The AIDPATH project’s successful integration of AI, metabolomics, and automated manufacturing processes is set to not only transform the landscape of CAR-T therapy but also to optimize hospital operations. This will enhance treatment accessibility for patients across Europe while facilitating the more efficient delivery of personalized therapies.

“The relocation of the AIDPATH platform to its final location at the University Hospital Würzburg is a key milestone in advancing the field of personalized medicine,” says Dr. Bastian Nießing, Project Coordinator at AIDPATH. “By bringing CAR-T cell therapy closer to the point of care, we are helping to reduce manufacturing complexities and costs, all with the primary goal of improving treatment outcomes for patients.”

The manufacturing platform is operated by the COPE software, developed by researchers at Fraunhofer Institute for Production Technology IPT, which allows for automated control via a no-code interface, and integrates the Facer bioreactor, a unique device capable of measuring glucose and lactate concentrations within the bioreactor every ten seconds, developed by AglarisCell from Spain. This high level of precision is critical to ensure optimal conditions for CAR-T cell production.

Ensuring ethical standards and data protection

A key part of AIDPATH’s work is to ensure that all advancements are made with the utmost respect for ethical standards. This includes ensuring that the patient cells used in CAR-T cell production are handled in accordance with bioethical principles and that patient data is protected in compliance with privacy regulations. Trust in AI applications in healthcare is crucial, and AIDPATH is committed to build that trust by prioritizing data security, confidentiality, and ethical considerations.

A promising future for personalized healthcare

As the AIDPATH platform begins its testing phase at the University Hospital Würzburg, the consortium looks forward to see how these innovations can transform the future of cancer treatment and personalized medicine. With the integration of AI and biotechnologies, AIDPATH is positioning Europe at the forefront of a new era in healthcare, one that promises to deliver safer, more effective, and more affordable treatments for patients around the world.

Project Consortium

- Fraunhofer Institute for Production Technology IPT, Aachen

- Würzburg University Hospital, Würzburg

- AglarisCell SL, Tres Cantos

- Ortec Logiqcare B.V. (Optimization Technology B.V. subsidiary), Zoetermeer

- Fraunhofer Institute for Cell Therapy and Immunology IZI, Leipzig

- Panaxea BV, Amsterdam

- Foundation for Research and Technology - Hellas, (FORTH), Patras

- IRIS Technology Solutions, Sociedad Limitada, Madrid

- Red Alert Labs, Maisons-Alfort

- Sartorius CellGenix GmbH, Freiburg

- Fundacio Clinic per a la recerca Biomedica, Barcelona

- SZTAKI Institute for Computer Science and Control, Budapest

- University College London, London