Synthesizing fine chemicals: Technological Advance in Production of Pharmaceuticals

Advertisement

Production of fine chemicals such as those used in pharmaceuticals is typically complex and laborious. An interdisciplinary team of Fraunhofer researchers worked together across different projects to devise a method modeled on a cascade, in which multiple successive stages of synthesis proceed without interruption. This is made possible through the use of novel catalysts in specially adjusted flow-through reactors. The new method makes the process of manufacturing drugs more efficient and conserves energy. In this way, the modular technology platform supports the production of pharmaceuticals in Germany as an industrial location.

Fine chemicals are viewed in the chemical industry as very high-value products. They are required wherever large quantities are less of a concern than precision effects and high purity levels, such as in the production of pharmaceuticals. Manufacturing fine chemicals is complex and typically requires multiple successive reaction steps. The methods used to synthesize them have been established for many years, but they have also largely reached their limits in technical terms.

Fraunhofer researchers have now developed an innovative synthesis process for manufacturing fine chemicals as part of two shared projects. While conventional methods rely on a sequence of different reactors and stirrer tanks, in which the product solution must be prepared and moved to a different vessel after every reaction for the next step, the new method involves creating the final product in a continuous synthesis cascade, ideally within a single reactor. This method significantly enhances process efficiency and makes production more sustainable by shortening retooling times and reducing the amount of energy needed. These benefits directly affect the carbon emissions from the synthesis process, along with its costs.

Four Fraunhofer institutes teamed up to achieve this: the Fraunhofer Institutes for Molecular Biology and Applied Ecology IME, for Silicate Research ISC, for Interfacial Engineering and Biotechnology IGB, and for Microengineering and Microsystems IMM.

Catalysis using enzymes and light

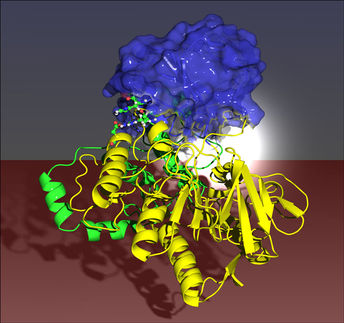

The process devised by the Fraunhofer researchers is based on an innovative combination of two catalysis methods. Photocatalysts, which are activated with light, are combined with enzymes, which also act as catalysts. The enzymes are either applied to transparent films, which immobilizes them, or used as particles in the reaction medium. Project manager Dr. Michaela Müller from Fraunhofer IGB explains the new method’s advantages: “This way, we keep the catalysts from floating around freely in the solution, which requires them to be filtered out or removed after every step in a time-consuming and laborious process. The immobilized enzymes or catalysts can stay in the reactor while the reaction product continuously forms. If the enzymes become inactive, they are easy to replace without having to interrupt the process.”

“The light-driven catalysis for the cascade reactions doesn’t require particularly high temperatures, so it is highly compatible with biocatalysis and also conserves energy as a result,” explains Dr. Thomas Rehm, the project manager at Fraunhofer IMM who specializes in sustainable synthesis in flow-through reactors. For maximum effectiveness in bringing the light into contact with the photocatalyst and the reaction solution, the flow-through reactors used are equipped with films or with thin, transparent plastic tubes known as capillaries. The input solution is either pumped through the reactor’s capillaries — including the catalyst particles and a gas to improve sediment transport — or fed in via the transparent polymer film used to carry the photocatalysts and enzymes.

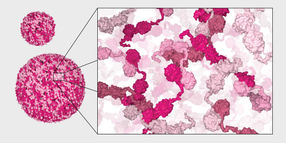

Because the cascade reaction uses enzymes, the new method is especially well suited to manufacturing the “chiral” fine chemicals frequently used in pharmaceuticals. These chemical compounds are based on molecules that have an exact mirror-image structure but cannot be superposed on each other through rotation, much like human hands. This is known as stereoisomerism. The chiral molecule can have completely different effects depending on the version, or isomer — the left or right hand, in this analogy. For this reason, deliberately producing only one isomer with as high a level of purity as possible is important in order to achieve maximum positive effect.

Technological advance in chemical production

To realize the novel catalytic method, the four Fraunhofer Institutes combined their respective research expertise and worked together in an interdisciplinary approach. This resulted in much more than just a new method: The Fraunhofer experts have developed a modular technology platform for producing various classes of fine chemicals. This means feasibility studies can be conducted for industry customers to tailor their desired processes to the individual reactions and catalytic combinations involved.

The pharmaceutical sector stands to benefit from this in particular, as the production technologies used in this industry have often reached their limits. More and more manufacturers are offshoring locations to cut production costs or purchasing active ingredients from other countries. “In the chemical industry, we need a new set of methods for state-of-the-art production that is also sustainable and cost-effective,” Müller says. “This will solidify the technological leadership of German pharmaceutical manufacturers as they compete on the global stage and make Germany once again an attractive production location.” In this way, the Fraunhofer researchers’ new development will also help to safeguard Germany’s drug supply going forward.